Recently, a metal cutting factory consulted our technical staff. When they recently used a metal cutting fluid produced in Guangxi to process metal, there was more foam. They tried to add other brands of metal cutting fluid defoaming agent to the aqueous cutting fluid. At the beginning, the effect was very good. The foam in the aqueous cutting fluid was defoamed very quickly, but after 10 minutes, the foam in the aqueous cutting fluid rose again. This problem made us very puzzled, so I found the Zilibon defoaming. The agent company consults.

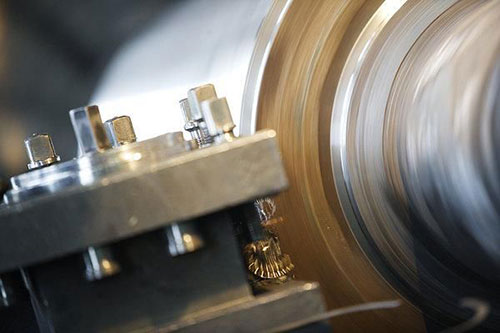

Metal cutting fluid defoamer for metal cutting

Our company's engineers believe that it is an important means to reduce the foam of the cutting fluid into the fully synthetic water-soluble cutting fluid. The most fundamental cause of the problem of cutting fluid foam is the formulation problem. Because of the defoamer he added, it will foam again in ten minutes. There are two reasons for this. In this case, there is a problem with the selected defoamer. There are many types of defoamers. A foaming agent is preferred. Either there is a problem with the way of adding, the defoaming agent can not be directly added into the cutting fluid, otherwise it will be easily filtered out, and it should be diluted with the working fluid and then added, so that it will not be filtered by the filtering system, the effect will be More lasting.

Choosing a good defoamer is the key point. Zilibon metal cutting fluid defoamer is the most suitable foam for this condition. The foam in the metal cutting fluid is broken instantly after the addition. The cutting fluid defoamer contains special modified polyether and fluorine. The raw materials are compounded by special process, which is very soluble in water. It is especially suitable for high temperature, strong acid and alkali, high shear force, excellent defoaming and antifoaming properties, acid and alkali resistance, no floating, no bleaching oil. It can be widely used for foam elimination and suppression of various harsh systems over a wide temperature range.

Recommended amount of metal cutting fluid: The amount of defoaming agent for cutting fluid is 0.05%~0.3% of the total volume, but the most economical dosage should be determined after the process test; it can also be mixed with other powder additives. .

Zilibon defoamer is a well-known defoamer company in China. It not only has 16 years of experience in defoaming application, but also has its own independent laboratory. It is specially designed for the research of defoaming agents for difficult to solve foam. We have a group of excellent Engineers, with their professional standards, have helped many customers solve their foam problems, and they have also received praise and recognition from customers. If you want to know more about defoamers, you can call us at +86 13929201380.

This article is from the manufacturer of Zilibon defoamer (http://www.zilibon.com/), please indicate the source if you need to reprint.

中文

中文

EN

EN