There are many kinds of metalworking fluids, and each metalworking fluid has a corresponding special defoaming agent. So when many metalworking fluid manufacturers choose antifoaming agents, they will face so many types of cutting fluid defoamers. There are doubts, do not know which cutting fluid defoamer is more suitable, the following Zilibon defoamer Xiaobian will solve this problem for everyone.

Cutting fluid defoamer in cutting fluid

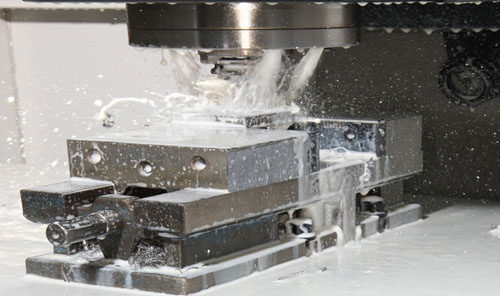

Production of cutting fluid foam

Cutting fluid is the most important additive in the process of metal cutting. It can improve the cutting efficiency, improve the precision and reduce the surface roughness of the work. It can also extend the service life of the tool and help the best results when cutting. While using the cutting fluid, a large amount of foam is produced on the surface of the cutting fluid. There are three main reasons for the foam: 1 The foam 2 caused by the liquid level of the cutting fluid is too fast, and the flow is too fast. There is no way to overflow more and more, resulting in a large amount of foam. There is no way to eliminate the 3 right angles in the design of the sink, or the nozzle angle of the cutting fluid is too straight to cause foam. This is the right to find Zilibon cutting fluid, will soon reveal the cutting fluid solution for you.

Cutting fluid manufacturers are worried about the problem

When many manufacturers choose cutting fluid defoamers, manufacturers are worried about the same problems. They worry that after using defoamer, the defoaming agent is not effective, the foaming time is not long enough, and there are precipitation, floating oil and rust prevention. Lubrication, cooling and other functions.

E-325 cutting fluid defoamer

Zilibon cutting fluid defoamer solution

The above-mentioned cutting fluid foam generation and the traders are worried about the problems in the process of using the defoaming agent. It is not a problem in the Zilibon cutting fluid defoaming agent. For example, the cutting fluid defoaming agent B-325: 1. Quickly dissolve in water, Special modified polyethers and fluorine-containing raw materials are produced by special processes. 2. In the environment of high temperature, strong acid and alkali, high shear force and high pressure, the defoaming can be maintained quickly and the foaming time is long. 3, in the application process will not precipitate, will not affect the cutting fluid anti-rust, oil, lubrication, cooling and other functions.

Zilibon Fine Chemicals - engaged in the research and development of defoamers for 17 years. It is the only manufacturer in Guangdong that cooperates with Tsinghua University to develop defoamers. The professional problem engineers provide one-on-one counseling solutions to solve your foam troubles. If you need defoamer, please click on the consultation window in the right corner for consultation, or call the national toll-free hotline: +86 13929201380.

This article is from the manufacturer of Zilibon defoamer (http://www.zilibon.com/), please indicate the source if you need to reprint.

中文

中文

EN

EN