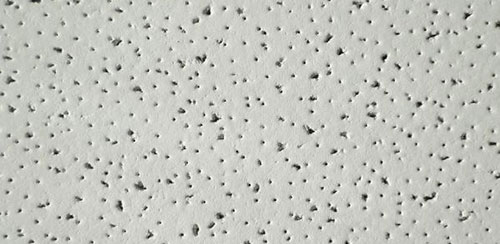

A customer in Shandong sent a defoamer for mineral wool board (hereinafter referred to as the sample). The requirement is that our defoamer should have the same appearance as the defoamer. The viscosity and content should be similar, but defoaming. The anti-foaming effect is better than the sample. Let's talk about how the Zilibon engineers came to meet the requirements of the Shandong customer.

Application of special defoaming agent for mineral wool board in mineral wool board

The engineer uses the laboratory instrument to extract all the components of the special defoamer for the mineral wool board sent by the customer, and analyze how the proportion of the defoamer ingredients they send is matched, and then according to the ratio of the defoamer. The method and the requirements of the customer were adjusted. After the test was successful, we sent the adjusted defoamer to the customer.

After five days, Mr. Li, a customer from Shandong, called and said that the defoamer completely met their requirements, and the defoaming speed was twice as fast as the original speed. Then we ordered it from here. 200kg.

Zilibon Laboratory is a research and development team consisting of three graduate students led by Dr. Haigui. In order to meet the requirements of our customers, Zilibon Shandong Defoamer can be customized to make a suitable defoamer for your product. No side effects, fast defoaming and strong foam suppression. Contact number: +86 13929201380.

This article is from the manufacturer of Zilibon defoamer (http://www.zilibon.com/), please indicate the source if you need to reprint.

中文

中文

EN

EN